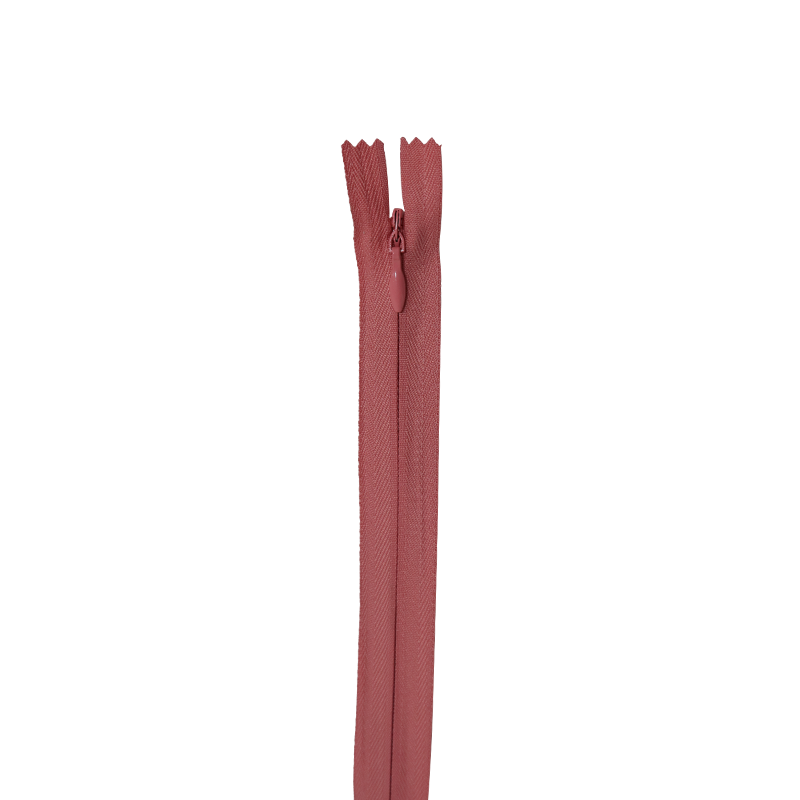

In order to ensure that the invisible zipper can perfectly blend with the fabric while maintaining smoothness and durability, its design structure can be optimized from the following aspects:

The teeth of the invisible zipper are usually small and finely designed to be consistent with the surface of the fabric to achieve an invisible effect. To optimize smoothness, a smooth tooth shape can be selected, and the teeth can be made tighter and flatter through precision processing, while avoiding sharp edges and reducing the possibility of jamming. The use of V-shaped or slightly curved teeth can better improve the smoothness of the zipper and avoid getting stuck between the teeth when pulling and closing. The tooth material should also be tough and wear-resistant, such as using wear-resistant nylon or high-strength polyester materials to ensure long-term durability.

The zipper strip is an important part of the invisible zipper that carries the fabric and zipper teeth. To ensure fit with the fabric, the strip should be made of soft but tough materials, such as specially treated polyester fibers, so that it is soft enough to fit the fabric and ensure that the zipper does not have an abrupt feeling on the fabric. At the same time, the thickness of the strip should be moderate, which can support the zipper structure and prevent deformation, but not be too heavy to affect the invisible effect. Choosing a high-density woven strip material can also help enhance its durability, especially for high-frequency use in clothing or home textiles.

Adding a layer of micro anti-stuck coating on the teeth and strips of the invisible zipper can improve the smoothness of the zipper. This coating can be an anti-static material or a self-lubricating material, such as Teflon coating, which can effectively reduce friction during the zipper pull. Especially for the zipper head part that is prone to jamming, adding a coating can avoid friction between the zipper head and the zipper teeth, making the user smoother when pulling and closing, and reducing the damage to the zipper teeth caused by jamming.

The zipper head is a key component for users to operate the zipper, which has a direct impact on smoothness and user experience. The zipper head of the invisible zipper should be designed to be flat and compact so that it fits the fabric better when pulling and closing, and reduces the prominent visual effect. Lightweight alloy materials can be used to improve the strength of the zipper head. The rail inside the zipper head should be finely polished to ensure that the contact surface with the zipper teeth is smooth and unobstructed for a better closing and zipping experience. In addition, designing a detachable or replaceable zipper head can enhance the maintainability of the invisible zipper.

To enhance the durability and stability of the invisible zipper, the closure structure of the zipper can be improved, such as adopting an automatic locking design, that is, automatically locking after the zipper head is fully closed to prevent the zipper from sliding open on its own. The beginning and end of the zipper can also be reinforced, using thickening or special sewing technology to ensure that the zipper is not easily damaged in the parts that are frequently closed and pulled. For longer zippers, a double locking structure can be used at the closure to further enhance its durability.

To achieve the invisible effect, the color of the invisible zipper's strips and teeth should match the fabric. More color options and even customized tones can be provided to ensure that it can be integrated and unobtrusive on various fabrics. In addition, the surface of the zipper strip can be textured to make it closer to the touch of the fabric. For example, for smooth silk fabrics, the strips can be treated with a glossy finish; for cotton or linen fabrics, matte strips can be designed to reduce visual differences.

The above measures can ensure that the invisible zipper maintains high smoothness and durability while ensuring visual invisibility, so that it can meet the diverse needs of products such as clothing and home textiles.

en

en  русский

русский 한국어

한국어 get a free quote

get a free quote