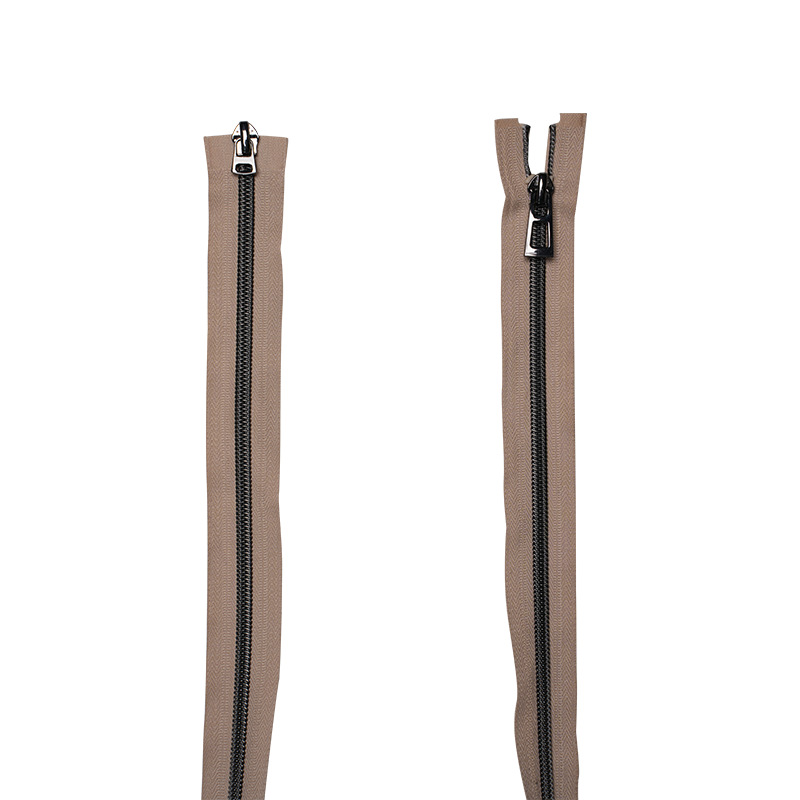

The design of the slider, slider type and tooth structure of the Finish Zipper are among the key factors that affect the performance of the zipper. They not only directly affect the functionality of the zipper, but also determine its durability, smoothness, safety, appearance and other performance. The following is the impact of the specific design of these three parts on the performance of the zipper:

The slider (or zipper head) is the key component used to pull the slider and open or close the zipper. The design of the slider not only affects the appearance of the zipper, but is also closely related to its functionality and comfort.

The appearance design of the slider has a direct impact on the overall beauty of the zipper. Fashionable slider design can enhance the grade of the product, especially in high-end clothing, luggage and outdoor products. Different shapes, colors and materials can match the overall design.

The shape and size of the slider will affect the smoothness of use. A well-designed slider can ensure smooth opening and closing of the zipper and reduce friction. For example, a smooth edge design can prevent the zipper from getting stuck, while an irregularly shaped slider may cause jamming, especially when used frequently.

The size and shape of the slider will also affect the feel. An ergonomically designed slider can improve the user's comfort. For example, a larger slider is easy to grip, while a smaller slider may be difficult to operate, especially in cold environments and not convenient enough when operating with gloves.

For some special-purpose zippers, such as anti-theft zippers or waterproof zippers, the slider design also needs to ensure its firmness to prevent accidental detachment or loss of function. The locking function of the slider is also an important consideration in the design, especially in sportswear or outdoor equipment, to ensure that the slider will not slide by itself due to external forces during use.

The material selection of the slider has a direct impact on durability and corrosion resistance. For example, metal sliders are more durable and more luxurious than plastic sliders, while plastic sliders are lighter but may be less durable.

The slider is one of the core components of the zipper, which controls the opening and closing state of the zipper. The type, structure and material of the slider have an important impact on the use effect of the zipper.

The design of the slider determines whether the zipper opens and closes smoothly. A more sophisticated slider design can effectively reduce friction when the zipper opens and closes, and improve the smoothness of use. The precision between the metal or plastic gears in the slider also affects the opening and closing effect of the zipper.

The material and craftsmanship of the slider affect its durability. Metal sliders are generally more wear-resistant than plastic sliders and are suitable for high-intensity use occasions. For some zippers that need to be pulled frequently, choosing a more sturdy slider is crucial.

The design of the slider needs to ensure that it fits tightly with the zipper gear, but not too tight to avoid jamming or poor engagement. A good slider design can make the zipper more durable and maintain high flexibility even under high-frequency use.

Some zipper sliders are equipped with a locking device to prevent the zipper from sliding on its own. This design is very important in some special applications, such as anti-theft zippers, waterproof zippers, etc., to ensure that the zipper does not accidentally open during use.

Some slider designs have multiple functions, such as two-way sliders (can be opened and closed in both directions), or sliders with additional functions (such as inlaid decorative elements, or enhanced waterproof functions). These multi-functional sliders are usually able to meet specific application needs.

The tooth structure of a zipper is the basis for its normal function. The shape, material, and matching method of the teeth directly affect the strength, durability, and smoothness of the zipper.

The teeth are usually made of materials such as metal, plastic, or nylon. Metal teeth (such as copper or aluminum teeth) are usually more durable and luxurious, suitable for heavy zippers such as bags and workwear; while nylon teeth are lighter and suitable for light products such as clothing and small bags. Choosing the right material is crucial to the durability of the zipper.

The shape of the teeth (such as V-shaped, U-shaped, square, etc.) and their matching method (such as double teeth, single teeth, etc.) will affect the smoothness of the zipper. Precision-designed teeth can make the zipper smoother and more secure when opening and closing, avoiding the zipper from getting stuck or not sliding smoothly.

The density and spacing (pitch) of the teeth determine the sealing and strength of the zipper. More dense teeth usually provide stronger closing force and better waterproof performance, but may affect the smoothness of opening and closing. Wider teeth are suitable for some lighter applications and can provide better smoothness.

The corrosion resistance of teeth, especially metal teeth, is very important, especially in humid or high-salt environments. If metal teeth are not treated with corrosion protection, they will easily rust or damage. Therefore, the teeth of zippers are often treated with nickel plating, zinc plating and other surface treatments to improve their corrosion resistance.

For waterproof zippers, the design of teeth needs special attention. The teeth of waterproof zippers may adopt special designs (such as embedded rubber sealing strips) to ensure that the zipper does not leak when closed. The matching accuracy of teeth and sealing strips is high, and any gap may cause waterproof failure.

The design of the pull head, the type of slider and the tooth structure are the three core factors that determine the use effect of Finish Zipper. They work together on the smoothness, durability, safety, functionality and appearance of the zipper. Reasonable design can significantly improve the performance of the zipper and meet the needs of different products and industries. Improper design may cause problems such as jamming, wear and damage of the zipper, affecting the consumer's experience. Therefore, the sophistication and innovation of zipper design are directly related to the market competitiveness and customer satisfaction of zipper products.

en

en  русский

русский 한국어

한국어 get a free quote

get a free quote